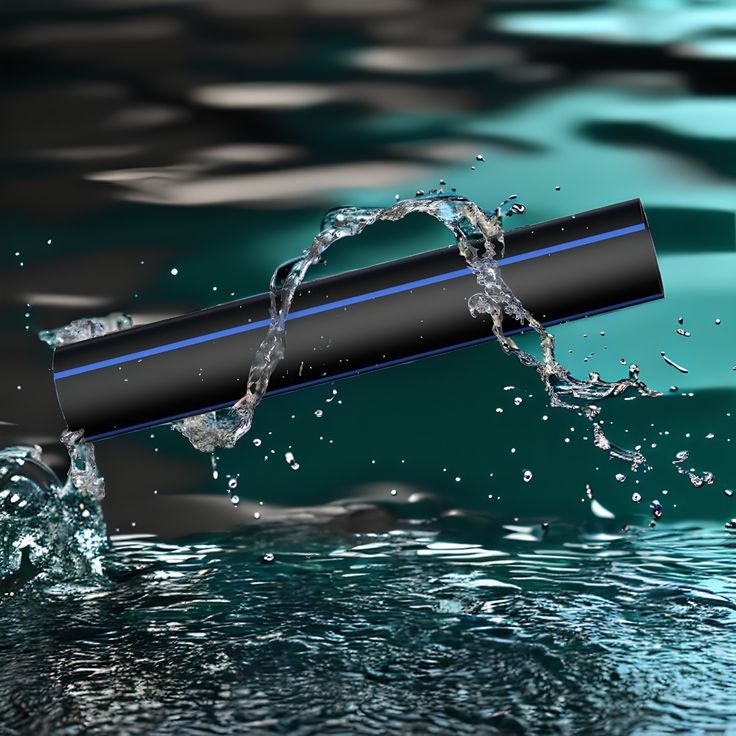

Are you struggling to find a durable, cost-effective, and eco-friendly solution for your piping needs? Whether it’s for water transportation, irrigation, or industrial applications, choosing the right type of pipe can feel overwhelming. This is where HDPE pipes (High-Density Polyethylene pipes) come in as a game-changer. Known for their flexibility, strength, and corrosion resistance, HDPE pipes have become a top choice for numerous industries worldwide.

What is an HDPE Pipe?

HDPE (High-Density Polyethylene) pipes are thermoplastic pipes made from high-density polyethylene resin. Their distinguishing feature is their flexibility, high strength-to-density ratio, and remarkable resistance to chemicals, corrosion, and UV rays.

Key Features of HDPE Pipes:

- Durability: HDPE pipes are designed to last for decades, even in harsh environments.

- Leak-Free Joints: They use fusion welding, ensuring strong, leak-free connections.

- Eco-Friendly: Fully recyclable and lightweight, they have a lower carbon footprint than traditional materials like PVC or steel.

- Cost-Effective: Their long lifespan and low maintenance make them a budget-friendly option.

Brownfield, a leading HDPE pipe manufacturer, ensures that its pipes meet stringent quality standards, making them ideal for varied applications.

Where Are HDPE Pipes Used?

HDPE pipes are versatile and find applications across multiple industries. Let’s explore their real-world uses:

1. Water Supply and Distribution

HDPE pipes are a popular choice for municipal water systems due to their resistance to corrosion, low leakage rates, and flexibility. They are widely used in:

- Drinking water distribution

- Sewer and drainage systems

- Rural and urban water supply projects

2. Irrigation Systems

Agricultural irrigation systems benefit immensely from HDPE coils and pipes. Their flexibility allows them to navigate uneven terrains, ensuring effective water distribution. Applications include:

- Sprinkler systems

- Drip irrigation systems

- Surface irrigation setups

Pro Tip: Brownfield offers customizable HDPE pipe fittings, making installations seamless and efficient for farmers.

3. Industrial Applications

Industries use HDPE pipes for transporting chemicals, gases, and other hazardous materials. Their chemical resistance ensures they don’t degrade over time.

- Chemical plants

- Oil and gas pipelines

- Industrial wastewater treatment

4. Mining and Slurry Applications

The mining industry relies on HDPE pipes for transporting slurries, tailings, and water. Their abrasion resistance makes them ideal for these demanding conditions.

5. Telecommunication and Electrical Conduits

HDPE pipes are extensively used as conduits for optical fiber cables, power lines, and telecommunication lines, thanks to their lightweight and durable nature.

Why Choose Brownfield for HDPE Pipes?

As one of the top HDPE pipe manufacturers, Brownfield stands out for its innovation, quality, and customer-focused solutions. Here’s why customers trust them:

- Wide Range of Products: From standard HDPE pipes to specialized HDPE coils and pipe fittings, Brownfield offers a comprehensive range of products.

- Custom Solutions: Tailored options to meet specific industry needs.

- Global Standards: Pipes and fittings comply with international quality certifications.

- Sustainability: Environmentally responsible manufacturing processes.

Benefits of HDPE Pipes Over Traditional Pipes

1. Corrosion Resistance

Unlike steel or iron pipes, HDPE pipes do not corrode when exposed to water or chemicals, extending their lifespan significantly.

2. Flexibility

HDPE pipes can be bent without cracking, making them ideal for areas prone to earthquakes or soil shifts.

3. Ease of Installation

Their lightweight design reduces transportation costs and simplifies installation. Brownfield’s HDPE coils are particularly useful for projects requiring continuous lengths of piping.

4. Low Maintenance

With fewer joints and high resistance to blockages, HDPE pipes require minimal maintenance, saving costs in the long run.

FAQs

Q1: Are HDPE pipes recyclable?

Yes, HDPE pipes are 100% recyclable, making them an eco-friendly choice for modern projects.

Q2: Can HDPE pipes handle high-pressure systems?

Absolutely. Brownfield’s HDPE pipes are designed to withstand high pressure, making them suitable for industrial and municipal applications.

Q3: What sizes do HDPE pipes come in?

HDPE pipes come in a variety of sizes and lengths. Brownfield offers customizable options to meet specific project requirements.

Conclusion

HDPE pipes are transforming the piping industry with their versatility, durability, and eco-friendly features. Whether you need a reliable solution for water supply, irrigation, or industrial processes, HDPE pipes offer unmatched benefits.

Brownfield, with its reputation for excellence in HDPE pipe manufacturing, ensures that you get top-notch products and support. Don’t hesitate to explore the advantages of HDPE pipes for your next project.

Let us know your thoughts or questions in the comments below. We’re here to help!